Sandvik Coromant and Mastercam collaboration deliver cost savings for customer

“For a small company like ours, it means everything to us having a big company like Sandvik behind you.”

Making collaboration simpler

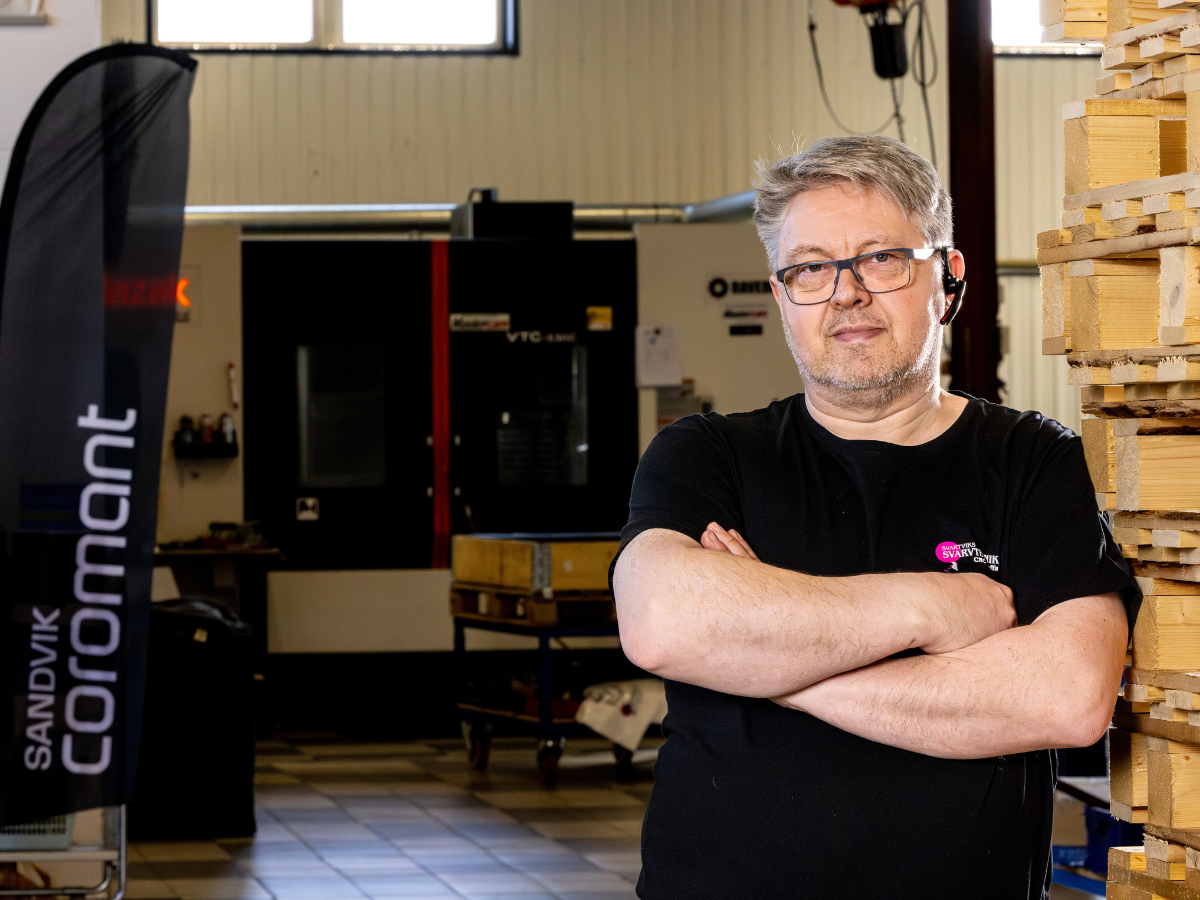

“At the beginning it was only tools, now Sandvik Coromant and Mastercam collaborate, they educated us and it’s hard to imagine we would be here if we didn’t have this help because, they have all this knowledge and experience that is hard for a small company to achieve otherwise,” said Jon Arne Fordal, Owner and Operator of Svartviks Svarvteknik AB.

CEO and daily manager, Linda-Marie Fordal shared that they manufacture all kinds of different parts. But one thing all the parts have in common is, “they are quite complicated to make, that’s why we need this kind of support we can get from both, Sandvik Coromant and Mastercam.”

Svartviks Svarvteknik has been operating since 1993, in Sundsvall, Sweden. They use a mix of CNC, manual and a robot machine to offer the most complete products possible.

Svartviks Svarvteknik has been operating since 1993, in Sundsvall, Sweden. They use a mix of CNC, manual and a robot machine to offer the most complete products possible.

For decades, they have been carrying out contract manufacturing for the engineering industry in machining, turning, milling and drilling, marking and assembly in accordance with each customers unique requirements.

Today, to ensure they are able to manufacture tools the right way – with the complexity of the parts they make, Fordal shared, they need to also have a great CAM solution. And having Sandvik Coromant, Mastercam, and Mastercam’s reseller in Sweden AME, collaborating provides cost savings and boosts their output.

A seamless solution

Magnus Karlsson, a Technical Sales Engineer with Mastercam’s reseller, AME, has been working with Svartviks for many years and believes the new tool library integrations is a great feature.

The technology allows him to quickly and efficiently resolve any customer questions. He is able to support customers at any time, in any place, with access to the software. Within a few clicks he’s able to support customers with any questions.

For example, Karlsson is at least a 2-hour drive from Svartviks, in 30 seconds or less he can be online viewing the same screen with the customers and answer any questions about the tools, methods, machine questions, or with NC code. For customers this helps with saving time.

For example, Karlsson is at least a 2-hour drive from Svartviks, in 30 seconds or less he can be online viewing the same screen with the customers and answer any questions about the tools, methods, machine questions, or with NC code. For customers this helps with saving time.

“I don't need to go anywhere. I don't need to have people come into our place. I just make a phone call. and I get the help I need, he can see my problem,” said Jon. “I don't need to describe it on phone, he can just see it on my screen. That’s one of the best solutions you can get.”

He emphasized that it was not like this 10 years ago. Adding how difficult it was to find a tool to make the parts they needed because there was a lot of material loss and the need for many other tools just to manufacture one part.

With the integrations between Sandvik Coromant and Mastercam and new tool cutting innovations like CoroPlex® YT, all-directional Y-axis turning, customers have solutions. “Sandvik has always helped us with every problem that we might have, no matter how big or small the problem, they’ve always been here for us,” Linda said.

“Thinking about Sandvik Coromant’s new Y-axis tool and Mastercam’s new method allows customers to use two inserts in the same tool," said Karlsson. "And being able to use the milling spindle, they can turn the tool from zero degrees to 360 degrees, so it's very flexible. And the design of the cutting forces getting directed up into the spindle, customers can achieve very low cutting forces, and this is very good for the energy of the machine.”

In addition to energy savings, Jon describes how they’ve also saved using the Y-axis method, “I think we probably saved about €150 per part.”

“We now rely on the process and feel confident using a robot to maintain production time when they’re not in the shop,” Jon said. “We were not able to do before and this is a huge cost savings for us.

Before the robot, an operator was necessary - all the time. Now, they can use the machine when the shop closes.

"If you only sell a tool or only sell software, then you will limit yourself. You need to be there to support your customer through the whole process," said Fredrik Svensson, Business Development at Sandvik Manufacturing Solutions. "If you're able to do that, then you will be very, very strong, and that’s the ambition that we have at Sandvik, to be a broader partner for our customers."

Other related articles you may like:

CoroPlus® Tool Library and Mastercam® CAD/CAM software

Sandvik Coromant CoroPlex® YT – All-directional Y-axis turning CoroPlus® Tool