Cimatron delivers high quality and automation for ALPLA mold shops most complex workflow

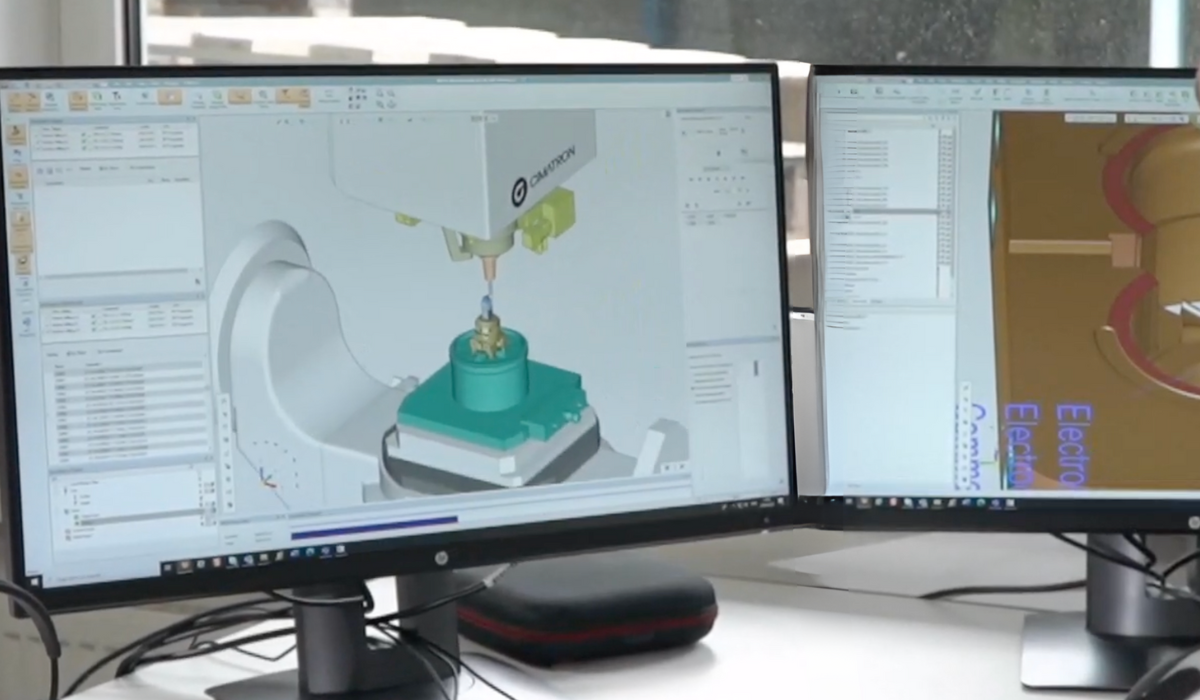

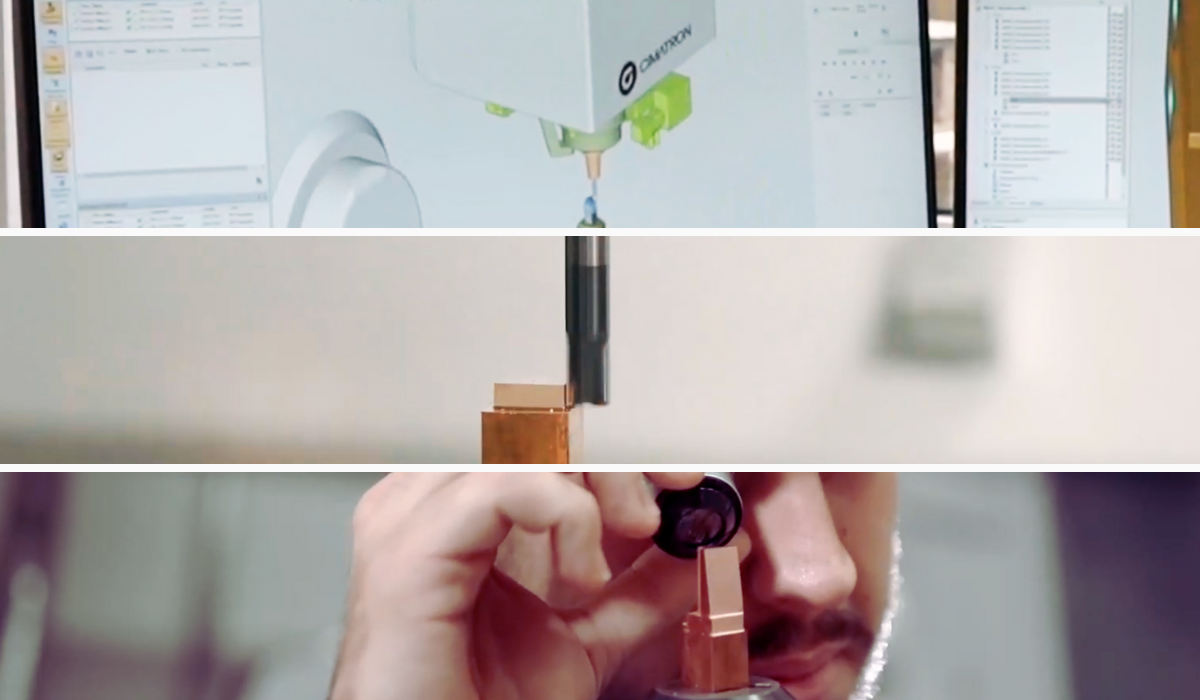

ALPLA decided Cimatron was the system of choice for their tool design and manufacturing processes, and electrode automation workflow.

Follow along as we explore why ALPLA, a mold packaging manufacturer with 23,300 employees in 190 locations, decided Cimatron was the system of choice for their tool design and manufacturing processes, and electrode automation workflow.

Overall, ALPLA's decision to adopt Cimatron reflects its commitment to staying at the forefront of the packaging industry and delivering innovative solutions that meet the evolving needs of its customers.

Read more about the impressive results achieved through this powerful collaboration.

“Cimatron has the competence on the software side, and we have a lot of skills in the field of automation for tool mold construction”

Tim Helbock, Technology Strategist for ALPLA Mold Shop.

Cimatron develops solutions that work to achieve the highest quality, irrespective of complexity across the value chain, helping ALPLA to achieve a high automation level.

By implementing advanced automation workflows and leveraging cutting-edge technology, ALPLA was able to significantly reduce lead times, increase productivity, and maintain their competitive edge in a fast-paced and ever-evolving industry.