How to import tool data and cutting parameters into a CAM system

Challenges of importing high-quality tool data with Mastercam

Digital data

All cutting tool vendors now have some form of digital data to represent their tools and cutting parameters. However, the formats used, and the completeness of the data are variable, and this presents challenges for automating the import into Mastercam for use in toolpath generation.

A CAM system, such as Mastercam, needs precise and accurate tool data since that data is used to machine a component. Inaccuracy in the tool data will likely result in errors on the final part and possibly other expensive issues in the machining process.

This blog looks at two distinct methods adopted by Mastercam to reliably import tool data and create Mastercam tool libraries. The resultant libraries are made available to customers with active Maintenance on the Mastercam Tech Exchange.

What is ISO13999?

ISO 13399 is an international standard that defines the representation and exchange of data related to cutting tools used in CAM systems. The standard was developed by the International Organization for Standardization (ISO) to provide a common language for describing cutting tool characteristics, enabling seamless communication and integration between various software applications and manufacturing machines. The standard utilizes the STEP format to communicate tool data.

Sandvik Coromant has been at the forefront of the development and implementation of this standard and their CoroPlus® Tool Library utilizes ISO 13399 for tool data representation. Mastercam has worked closely with Sandvik Coromant in recent years to support the standard for tool import. For those tool vendors with ISO13399 format data, this is the preferred route for bringing that data to Mastercam.

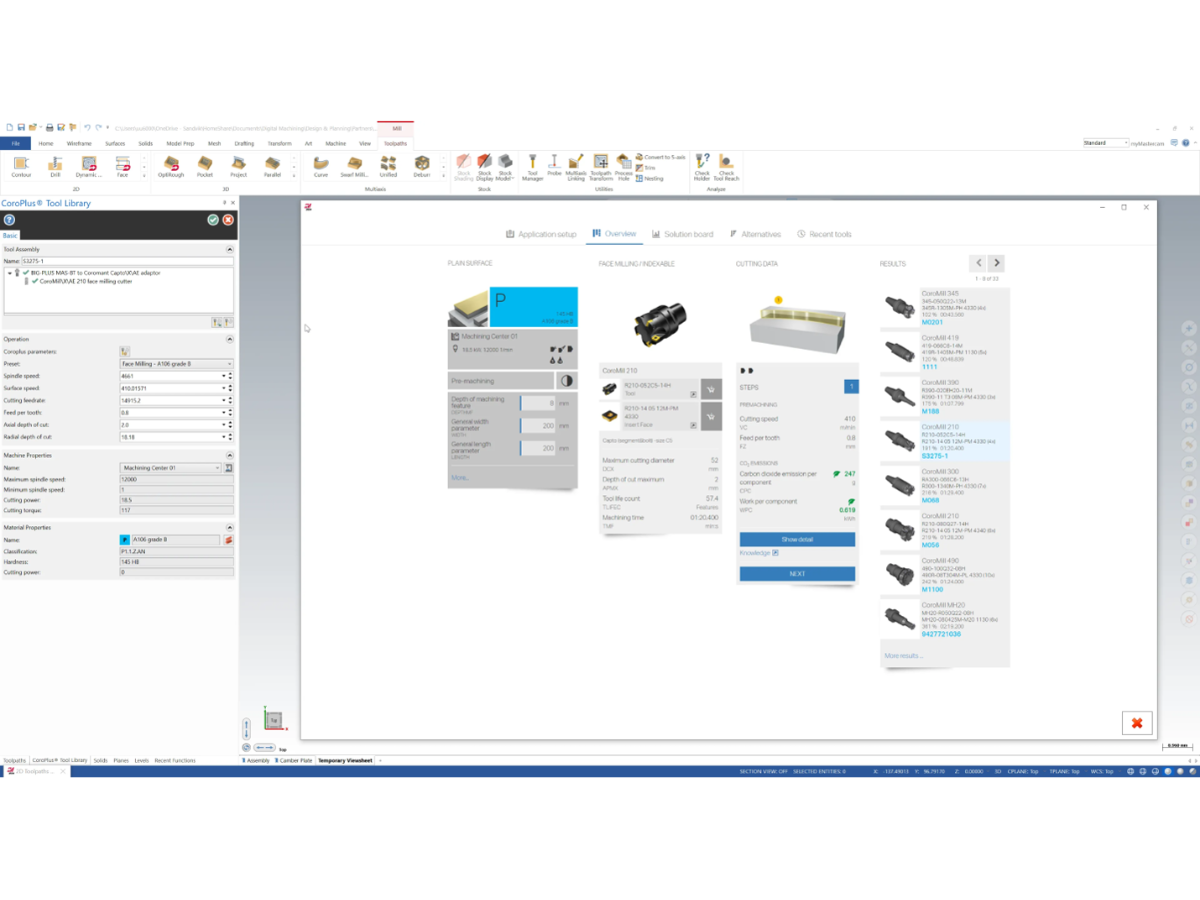

Connecting Mastercam and CoroPlus® Tool Library

Over the last year, Mastercam collaborated with Sandvik Coromant to build an integration with the latest generation of the Sandvik Coromant CoroPlus tool library, a comprehensive database of cutting tools and related data. The goal for the project was to provide much improved integration between the two products, allowing Mastercam customers to easily consume CoroPlus tool data and cutting parameters in the CAM programming process.

These initially were related to the mapping of the CoroPlus data to the equivalent Mastercam representation. This was not a 1-1 mapping and, in some cases, the Mastercam data format needed to be extended to support everything present in CoroPlus.

Sandvik Coromant and Mastercam worked closely together to build a one-year development culminating in the release of Mastercam 2024 in June 2023. There were two distinct parts to the development: the add-in application that connected the CoroPlus Tool Library to Mastercam, and the enriched interfaces in Mastercam that support the import of tool data. The final add-in application is now available directly from the Sandvik Coromant website.

Sandvik Coromant and Mastercam worked closely together to build a one-year development culminating in the release of Mastercam 2024 in June 2023. There were two distinct parts to the development: the add-in application that connected the CoroPlus Tool Library to Mastercam, and the enriched interfaces in Mastercam that support the import of tool data. The final add-in application is now available directly from the Sandvik Coromant website.

A major highlight of this project is that the framework developed can now be used by other tool vendors to build ISO 13399 based integrations with Mastercam. The framework includes an ISO 13399 file reader, a tool data validation API, a user interface panel architecture, and methods to inject cutting parameters into Mastercam operations.

Creating native Mastercam tool libraries using JSON and CAD data

As mentioned earlier, every tool vendor has digital tool data. While some have gravitated to ISO 13399, many still have tool data in proprietary formats. For this reason, Mastercam has developed import tools that use JSON to map vendor data to native Mastercam libraries. The vendor’s tool geometry is supplied in STEP or DXF format which are widely available. All other properties are represented in JSON.

What is JSON?

JSON (JavaScript Object Notation) is a lightweight and widely used data interchange format. It serves to structure and represent data in a human-readable format that is easy for both humans and computers to understand.

JSON was originally derived from a subset of the JavaScript programming language, but it's now a language-independent format commonly used for data exchange between different programming languages and platforms.

JSON was originally derived from a subset of the JavaScript programming language, but it's now a language-independent format commonly used for data exchange between different programming languages and platforms.

Creating Mastercam native tool libraries using JSON

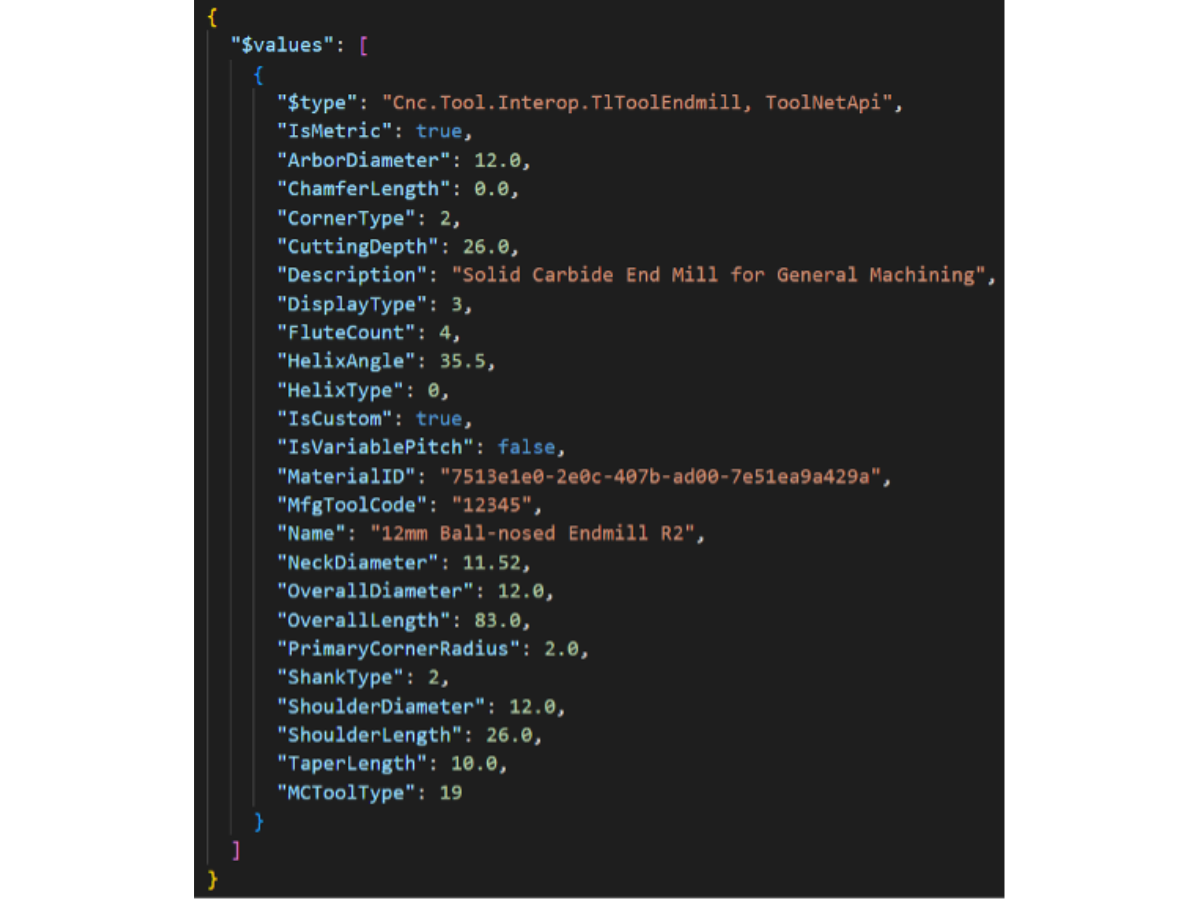

The Mastercam tool definition is made up of three basic categories of data.

- The general properties of the tool such as the tool name, tool number, manufacturer, etc.

- The geometric properties that make up the parametric definition of the tool. The parametric definition is used to generate toolpath motion and is a lightweight geometric representation of the tool.

- The geometric model of the tool. This is often more detailed than the parametric definition and is used to derive stock models and detect collisions.

The Mastercam JSON representation for a bull-nosed endmill is shown here. The manufacturer’s ID (MfgToolCode in the JSON image to the right), or EDP number of the tool, is typically used to uniquely identify a tool and provides a link between the JSON definition and the CAD file. Once the vendor sending the tool data maps their information to this format, a native Mastercam tool library file is created.

Typically, vendors create tool libraries for a family or several families of related tools. They are then distributed by the Mastercam Tech Exchange.

The key benefit of this method is the flexibility to map tool data from almost any source and no requirements on ISO 13399 data format.

The key benefit of this method is the flexibility to map tool data from almost any source and no requirements on ISO 13399 data format.

There are good graphical data mapping tools to assist in the conversion to Mastercam JSON format (such as Altova® MapForce®). Mastercam also provides diagnostic tools, allowing the parametric and geometric tool definitions to be compared for errors and inconsistency.

Key takeaways for importing tool data

We have walked through two different approaches for importing tool data into Mastercam. If you have ISO 13399 format data, then the first approach is the starting point. For all other data, JSON is the best technique. Mastercam has more technical documentation and support available to help you get started.

While speaking with Rich Taft, Technical Manager at Mastercam, about these topics, I asked him two questions. What are the key takeaways? And what’s next on the roadmap for tool data?

The key takeaway is the need for continuous and transparent communication around development topics.

The key takeaways are:

- The need for continuous and transparent communication around the development topics.

- Clearly identifying the work required for each contributor is vital.

- Leverage the latest agile development methodology and collaboration tools to keep things moving through the development cycle.

Turning tools have different challenges, there is a need to support tools, holders, and inserts as component libraries, or fully defined assemblies depending on the source of the data.