Generative AI for shop floor transformation

Learn how generative AI can help make the shop floor more efficient.

How AI is changing manufacturing?

Generative AI is transforming the manufacturing industry, bringing advanced technology to broader audiences for improved operational efficiency and innovation.

Generative AI is going to change how we make things. It will help us work smarter, generate new ideas, and meet our customers' needs. As we become more familiar with these technologies, the future looks bright for companies that use AI.

Generative AI and manufacturing

In this blog post, we'll discuss what generative AI is, why it's becoming more practical, and how it can help solve specific challenges in the manufacturing industry. We'll also explore future possibilities and share a genuine perspective on how generative AI can promote sustainable growth, boost human creativity, and free people from repetitive tasks.

Generative AI is rapidly changing industries around the world, including manufacturing. This advanced technology provides great opportunities to improve efficiency, create innovative product designs, and meet customers' changing needs.

What is Generative AI?

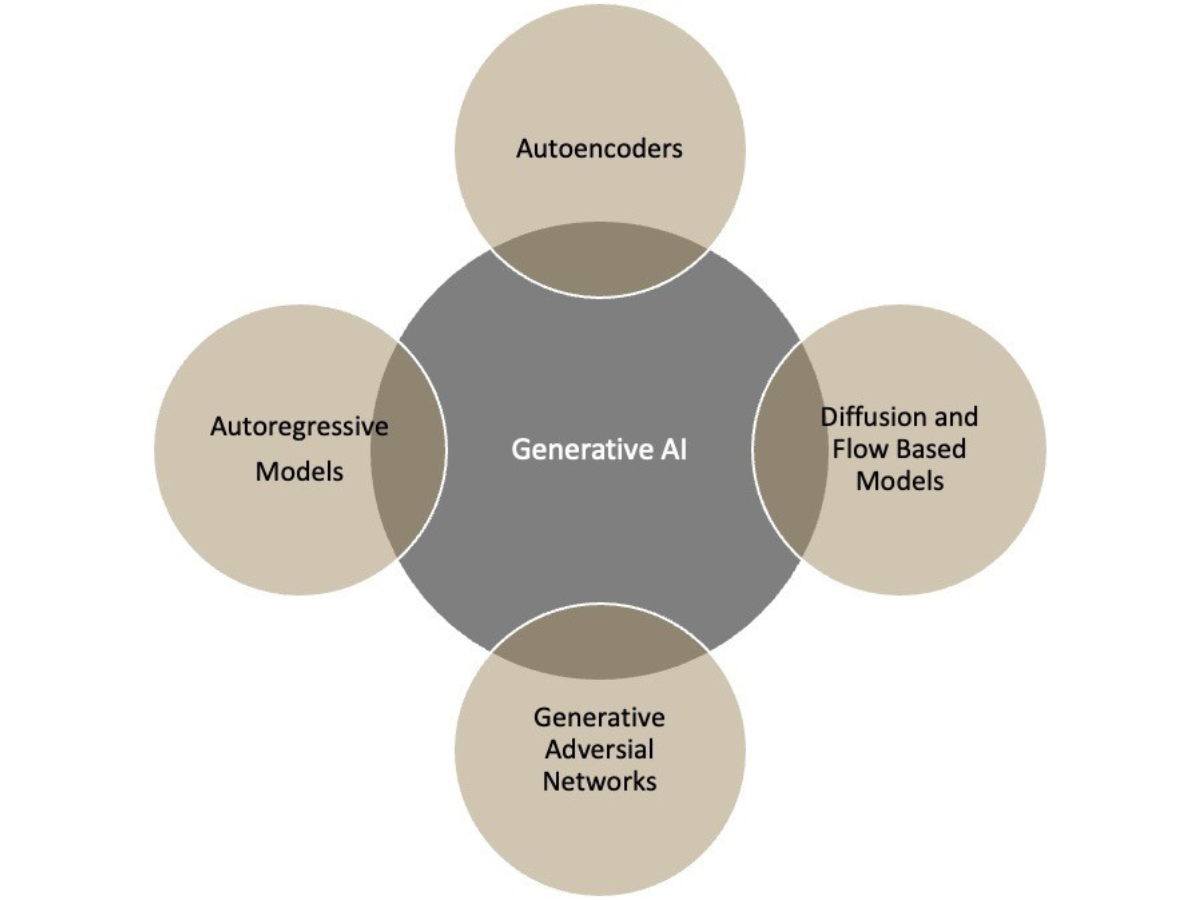

Let’s start from the beginning. Generative AI is a technology that can create new data, such as text, images, and sounds. It learns from large sets of information to generate this new content. Some important methods to enable generative AI:

- Autoencoders: These simplify complex information and can be used to create new content, which can be helpful for improving digital simulations and optimizing manufacturing processes.

- Autoregressive Models: These generate content step by step, making them useful for predicting trends and optimizing production schedules.

- Generative Adversarial Networks (GANs): These are used to create very realistic images and simulations, which can be helpful in approximately assessing different scenarios for a complex system based on various data sources in hand, i.e., shop floor, computational data (i.e., previous simulations), etc.

- Diffusion and Flow-Based Models: They help to simplify and analyze data, which can be useful for design for manufacturing.

The Rise of Generative AI: What Changed?

Generative AI enables machines to create new and unique content such as text, images, and sounds, and has seen significant advancements in recent years.

These developments, which is transforming various industries and applications, are driven by several key shifts that have occurred over the past decade, which are as the following:

- Faster computers: The speed and power of computers have increased tremendously, making it possible to use more advanced AI models.

- More data: There is an abundance of data available for training AI models, which provides a rich resource for improving AI technology.

- Lower costs: The expense of training AI models has decreased, making this advanced technology more affordable and accessible.

- Foundation models: Pretrained AI models have made it easier to apply AI to different tasks, requiring minimal additional training for specific uses.

Importance for customers

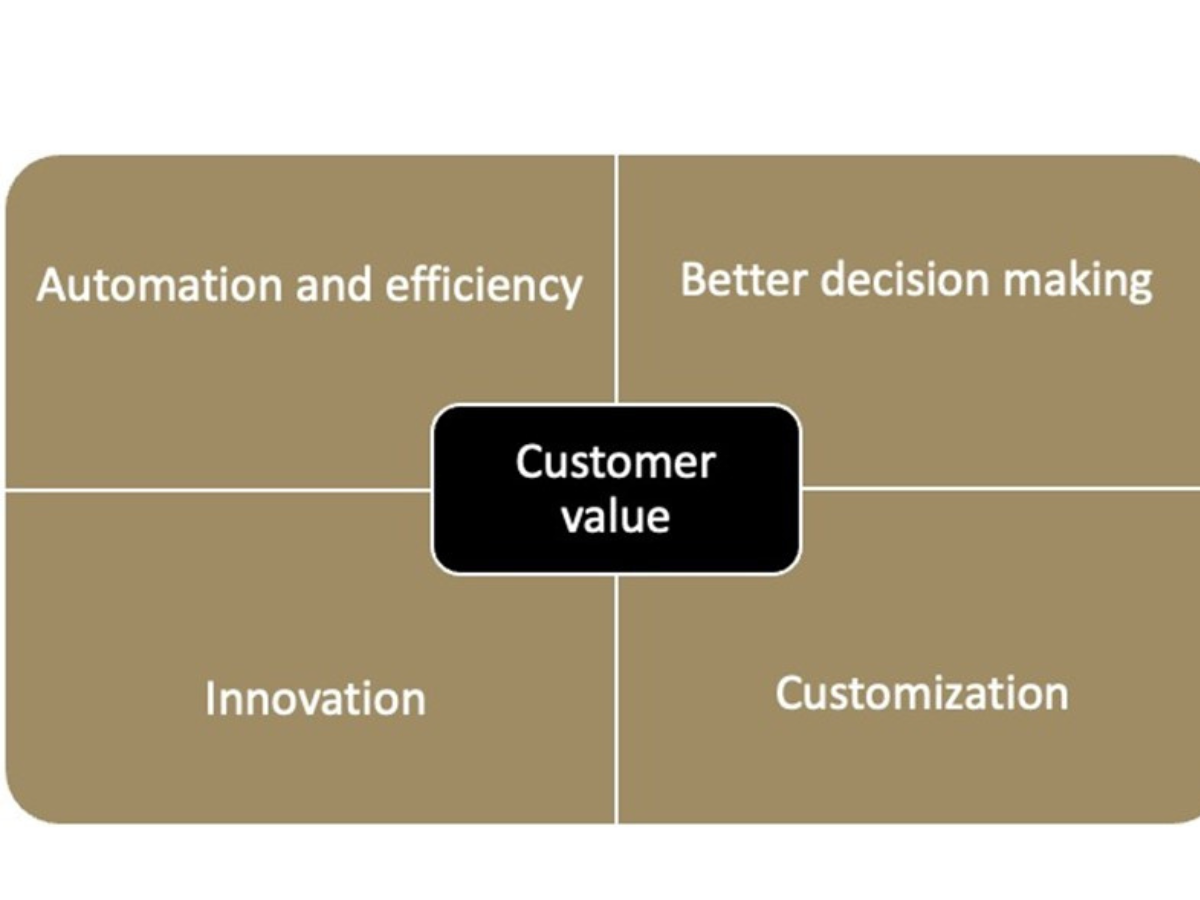

This new technology brings many advantages for those working in manufacturing.

Generative AI has the potential to revolutionize various aspects of the industry, it can aid in producing parts more efficiently in a customized and innovative way while continuously assisting in decision-making.

This advanced technology is not only changing how products are designed and made but also enhancing the overall processes in manufacturing such as:

- Automation and efficiency: Using AI to automate complex tasks means less manual work, which makes things run smoother and more accurately.

- Better decision-making: AI can analyze large data sets and give us useful insights, enabling us to make smarter decisions.

- Customization: Generative AI lets us create personalized solutions that fit each customer's needs.

- Innovation in product design: AI helps us create new and better designs and determine the best features for our products, which saves time and money.

Addressing customer needs

Generative AI is changing the manufacturing industry by meeting customer needs and improving production processes. This advanced technology offers numerous benefits that make it well-suited for modern manufacturing. It can help us to be better at:

- Decision making: AI can help make smarter decisions early in the process by analyzing trends and predicting outcomes.

- Designing better parts: AI helps design complex and lightweight parts, which makes them more sustainable and resource efficient.

- Improving automation: When AI is integrated with existing automation systems, the shop floor becomes more connected and efficient.

- Quality control: AI can be used for real-time inspection and quality control, which means better quality and fewer mistakes.

- Customization: AI enables manufacturing processes to be more flexible, making it easier to meet specific customer needs.

Humans at the center: boosting human creativity

Generative AI meets business needs and boosts human creativity, making work more satisfying and innovative.

By handling repetitive tasks, AI lets people focus on more meaningful and inventive work.

- Automating routine tasks: Generative AI can do data entry, basic analysis, and repetitive jobs, freeing up time for people to solve more complex problems. This makes better use of time, labor, energy, materials, capital, data, and intelligence.

- Boosting creativity: With AI handling boring tasks, engineers and designers can spend more time creating new product designs and improving production processes. This leads to higher productivity, efficiency, and quality, reducing risk and increasing profits.

- Helping make decisions: AI gives insights and suggestions, working with people to improve decision-making. This can lead to more innovative solutions and better outcomes, making business operations more sustainable, flexible, responsive, and agile.

- Improving quality of life: Integrating AI improves health, safety, customer satisfaction, and knowledge transfer. Generative AI promotes freedom, creativity, awareness, and connectedness, letting people focus on more meaningful and innovative work, making jobs more satisfying and enjoyable.

Building knowledge products with AI

Generative AI not only improves how we make things but also helps us to create knowledge products. Today, software systems and shop floor systems create a lot of discrete information; however, relating to this data or efficiently using the solutions is not always straightforward. The manufacturing software are advanced solutions that can use AI to better develop, manage, and apply knowledge within the manufacturing environment:

- Smart knowledge systems: AI can help us create systems that learn from data and provide insights, recommendations, and strategies for continuous improvement.

- Data insights: AI can analyze large amounts of data to find patterns and trends, turning raw data into valuable knowledge that helps us make better decisions and generate new ideas.

- Personalized training: AI can create training programs that are tailored to each person's job and what they need to learn, helping everyone get better at what they do.

Future possibilities

The potential of AI in manufacturing is enormous, offering to revolutionize the industry in ways that will enhance efficiency, innovation, and sustainability. As AI technology continues to evolve, it opens up a world of possibilities that can significantly contribute to transforming manufacturing processes and practices. Some exciting future possibilities of AI in manufacturing can include things such as:

- Better simulation and optimization systems: AI can help run advanced engineering simulations for optimization and design purposes in a simpler and faster way. Making advanced technology accessible.

- Teamwork with AI: In the future, AI could work with people on the factory floor, giving real-time help and suggestions for improvement. Knowledge products help teams work together by giving them a single place to share their insights and strategies.

- Self-optimizing systems: AI can help to reach self-optimizing assets on the shop floor one day, coupled with adjacent technologies of sensory systems and physics-based simulation infrastructure.

- Greener Manufacturing: AI can help in designing and using more eco-friendly manufacturing processes, cutting down on waste and reducing harm to the environment.

At Sandvik, we are dedicated to helping our customers to optimize their manufacturing processes and shop floor practices, cutting down on manual work, and unleashing their creativity with the power of technology. Our goal is to assist and be with them in bringing their ideas to life effectively and faster.

If you liked this article, here are similar topics you might like:

5 tips to improve shop floor management